7/3.05mm, 7/3.45mm, 7/4.0mm, 19/1.8mm, 19/2.3mm. Brin de fil en acier galvanisé (GSW)

Info de Base

N° de Modèle.

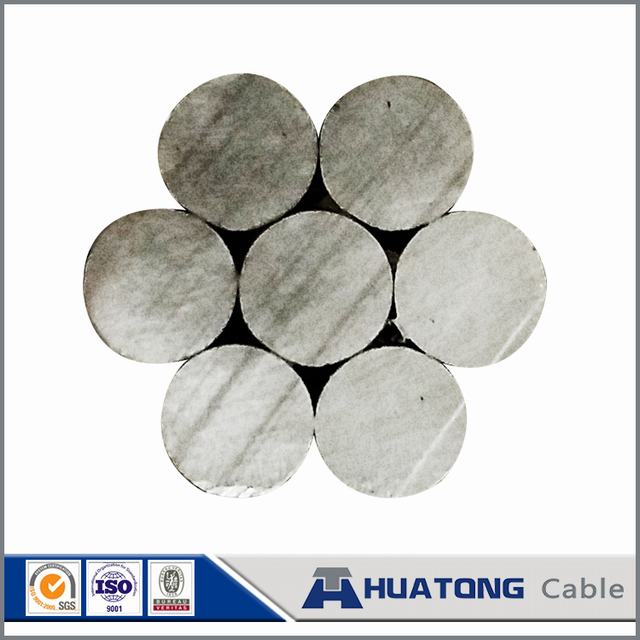

strand galvanized steel wire

Type

Isolé

Type de conducteur

Écrin

Demande

Aérien

Matériau isolant

Nu

Forme Matériel

Fil rond

Certificat

ISO9001 ,

CE ,

CCC

CE ,

CCC

Info Supplémentaire

Marque Déposée

Huatong

Emballage

All Wooden or Coils as Per Your Request

Origine

Zhengzhou, China

Code SH

731210

Capacité de Production

5000tons /Month

Description de Produit

Brin de fil en acier galvanisé(GSW)

Fil d’acier Galvanzied haut carbone;

Fil d’acier Galvanzied faible en carbone

Standard :

ASTM B498,l’ASTM B475, GB/T3428-2002,BS 1052et 3607

Le volet wireDiameter : 7/1.67mm, 7/1.85mm, 7/1.9mm, 7/2.00mm, 7/2.10mm, 7/2.67mm

7/3.05mm, 7/3.45mm,7/4.0mm, 19/1.8mm,19/2.3mm.

L’application Brin de fil en acier galvanisé est adapté pour hanger, câble de communication et de la suspension, plus de tête de ligne de transmission d’alimentation, objet fixe et driftbolt, etc.

Les produits standard peuvent être fabriqués en fonction de Go en standard, la norme CEI, la norme ASTM, BS et DIN standard et d’autres andcustomers standard’sexigences spécifiques.

| La norme CEI61089 | |||||||||||

| Zone Norminal | Nom de code | Domaine /mm2 | Nombre de fils | /Mm de diamètre | Poids /(kg/km) | Charge de rupture Norminal /kN | D.C la résistance à la (20ºC)/ (Ω/km) | ||||

| Fil unique | L’échouement Le fil |

JGIA | JGIB | JG2A | JG3A | ||||||

| 30 | 4 | 27.1 | 7 | 2.22 | 6.66 | 213.3 | 36,3 | 33,6 | 39,3 | 43.9 | 7.1445 |

| 40 | 6.3 | 42,7 | 7 | 2.79 | 8.36 | 335,9 | 55,9 | 51.7 | 60.2 | 67,9 | 4.5362 |

| 65 | 10 | 67,8 | 7 | 3.51 | 10.53 | 553.2 | 87,4 | 80,7 | 93,5 | 103 | 2.8578 |

| 85 | 12.5 | 84,7 | 7 | 3.93 | 11.78 | 666.5 | 109.3 | 100,8 | 116,9 | 128,8 | 2.2862 |

| 100 | 16 | 108,4 | 7 | 4.44 | 13,32 | 853.1 | 139,9 | 129 | 199,7 | 164 | 1.7861 |

| 100 | 16 | 108,4 | 19 | 2.7 | 13.48 | 857 | 142.1 | 131.2 | 152,9 | 172,4 | 1.7944 |

| 150 | 25 | 169,4 | 19 | 3.37 | 16,85 | 1339.1 | 218,6 | 201,6 | 238,9 | 262,6 | 1.1484 |

| 250 | 40 | 271.1 | 19 | 4.26 | 21,31 | 2141.6 | 349.7 | 322.6 | 374.1 | 414.1 | 0.7177 |

| 250 | 40 | 271.1 | 37 | 3.05 | 21.38 | 2148.1 | 349.7 | 322.6 | 382.3 | 420.2 | 0.7196 |

| 400 | 63 | 427 | 37 | 3.83 | 26.83 | 3383.2 | 550.8 | 508,1 | De 589,3 | 649 | 0.4569 |

| La norme ASTM A475 | ||||||

| Nombre de fil/Dia. | Env.Strand Dia. | Grade Siemem Martin | Le grade de haute résistance | Grade extra-haute résistance | Poids env. | |

| Pouce | Mm | KN | KN | KN | Kg/km | |

| 3/2.64 | 7/32 | 5.56 | 10.409 | 15.569 | 21.796 | 131 |

| 3/3.05 | 1/4 | 6.35 | 13.523 | 21.04 | 29.981 | 174 |

| 3/3.05 | 1/4 | 6 35 | – | 174 | ||

| 3/3.30 | 9/32 | 7.14 | 15.035 | 23.398 | 33.362 | 204 |

| 3/3.68 | 5/16 | 7.94 | 18.193 | 28.246 | 40.479 | 256 |

| 3/4.19 | 3/8 | 9,52 | 24.732 | 37.187 | 52.489 | 328 |

| 7/1.04 | 1/8 | 3.18 | 4.048 | 5.916 | 81.4 | 49 |

| 7/1.32 | 5/32 | 3.97 | 6.539 | 9.519 | 130.78 | 76 |

| 7/1.57 | 3/16 | 4.76 | 8.452 | 12.677 | 177.48 | 108 |

| 7/1.65 | 3/16 | 4.76 | – | 118 | ||

| 7/1.83 | 7/32 | 5.56 | 11.387 | 17.126 | 24.02 | 145 |

| 7/2.03 | 1/4 | 6.35 | 14.012 | 21.129 | 29.581 | 181 |

| 7/2.36 | 9/32 | 7.14 | 18.905 | 28.469 | 39 812 | 243 |

| 7/2.64 | 5/16 | 7.94 | 23.798 | 35586 | 49,82 | 305 |

| 7/2.77 | 5/16 | 7.94 | ~ | 335 | ||

| 7/3.05 | 3/8 | 9,52 | 30.915 | 48.04 | 68.503 | 407 |

| 7/3.68 | 7/16 | 11 11 | 41.591 | 64.499 | 92.523 | 594 |

| 7/4.19 | 1/2 | 12.7 | 53.823 | 83.627 | 119.657 | 768 |

| 7/4.78 | 9/16 | 14.29 | 69.837 | 108.981 | 155.688 | 991 |

| 7/5,26 | 5/8 | 15,88 | 84.961 | 131.667 | 185.605 | 1211 |

| 19/2.54 | 1/2 | 12.7 | 56.492 | 84.961 | 118.768 | 751 |

| 19/2.87 | 9/16 | 12.49 | 71.616 | 107.202 | 149.905 | 948 |

| 19/3.18 | 5/8 | 15,88 | 80.513 | 124.995 | 178.819 | 1184 |

| 19/3.81 | 3/4 | 19.05 | 116.543 | 181.487 | 259.331 | 1719 |

| 19/4,50 | 7/8 | 22.22 | 159.691 | 248.211 | 354.523 | 2352 |

| 19/5,08 | 1 | 25,4 | 209.066 | 325.61 | 464.839 | 2384 |

| 37/3.63 | 1 | 25,4 | 205.508 | 319.827 | 456.832 | 3061 |

| 37/4.09 | 11/8 | 28.58 | 262 | 407.457 | 58l.827 | 4006 |

| 37/4.55 | 11/4 | 31 75 | 324.72 | 505.318 | 721.502 | 4833 |

| BS 183:1972 | |||||||||

| Nombre de fils/Dia. | Env. Le volet de dia. | Minimum de charge de rupture du volet | Poids env. | ||||||

| Grade 350 | Grade 480 | Grade 700 | Grade850 | Grade 1000 | Grade 1150 | Grade 1300 | |||

| Mm | KN | KN | KN | KN | KN | KN | KN | Kg/km | |

| 3/1,80 | 3.9 | 2.65 | 3.66 | – | 60 | ||||

| 3/2.65 | 5.7 | 5.8 | 7.95 | – | 130 | ||||

| 3/3,25 | 7 | 8.7 | 11.95 | – | – | 195 | |||

| 3/4.00 | 8.6 | 13.2 | 18.1 | – | 295 | ||||

| 4/1,80 | 4.4 | 3.55 | 4.9 | – | 80 | ||||

| 4/2.65 | 6.4 | 7.7 | 10,6 o | – | 172 | ||||

| 4/3,25 | 7.9 | 11.6 | 15.9 | – | 260 | ||||

| 4/4.00 | 9.7 | 17.6 | 24.1 | 35,2 | 390 | ||||

| 5/1.50 | 4.1 | 3.1 | 4.24 | 6.18 | – | 69 | |||

| 5/1,80 | 4.9 | 4.45 | 6.1 | 8.9 | 95 | ||||

| 5/2.65 | 7.2 | 9.65 | 13.25 | 19.3 | – | 220 | |||

| 5/3,25 | 8.8 | 14.5 | 19.9 | 29 | – | 320 | |||

| 5/4.00 | 10.8 | 22 | 30.15 | 43,95 | 490 | ||||

| 7/O.56 | 1.7 | 0,6 | 0.83 | 1.2 | 1.7 | 1.98 | 2.24 | 14 | |

| 7/0 71 | 2.1 | 0,97 | 1.33 | 1 94 | 2.75 | 3.19 | 3.6 | 28 | |

| 7/0,85 | 2.6 | 1.39 | 1.9 | 2.8 | 3.95 | 4.57 | 5.15 | 31 | |

| 7/0.90 | 2.7 | 1.55 | 2.14 | 3.1 | 4.45 | 5.12 | 5.8 | 35 | |

| 7/l.00 | 3 | 1.92 | 2.64 | 3.85 | 5.5 | 6.32 | 7.15 | 43 | |

| 7/1,25 | 3.8 | 3.01 | 4.1 | 6 | 8.55 | 9,88 | 11.15 | 67 | |

| 7/1.40 | 4.2 | 3.75 | 5.17 | 7.54 | 9.16 | 10.75 | 12.35 | 14 | 84 |

| 7/RS* | 4.3 | 3.85 | 5.28 | 7.7 | 9.35 | 11 | 12.65 | 14.3 | 86 |

| 7/1.60 | 4.5 | 4.9 | 6.75 | 9,85 | 11.95 | 14.1 | 16.2 | 18.3 | 110 |

| 7/1,80 | 5.4 | 6.23 | 8.55 | 12.45 | – | 17.8 | 20.5 | 23.2 | 140 |

| BS 183:1972 | |||||||||

| Nombre de fils/Dia. | Env.Strand Dia. | Minimum de charge de rupture du volet | Poids env. | ||||||

| Grade 350 | Grade 480 | Grade 700 | Grade 850 | Grade 1000 | Grade 1150 | Grade 1300 | |||

| Mm | KN | KN | KN | KN | KN | KN | KN | Kg/km | |

| 7/2.00 | 6 | 7.7 | 10.55 | 15.4 | 22 | 25.3 | 28.6 | 170 | |

| 7/2.36 | 7.1 | 10.7 | 14.7 | 21.4 | 30.6 | 35,2 | 39,8 | 240 | |

| 7/2.65 | 8 | 13.5 | 18.5 | 27 | 38,6 | 44,4 | 50.2 | 300 | |

| 7/3.00 | 9 | 17.3 | 23,75 | 34,65 | 49.5 | 56,9 | 64,3 | 392 | |

| 7/3.15 | 9.5 | 19.1 | 26.2 | 38,2 | 54055 | 62,75 | 70,9 | 430 | |

| 7/3,25 | 9.8 | 20.3 | 27,85 | 40,65 | 58.05 | 66.8 | 75,5 | 460 | |

| 7/3.65 | 11 | 25.6 | 35,5 | 51,25 | 73.25 | 84,2 | 95.2 | 570 | |

| 7/4.00 | 12 | 30.9 | 42.2 | 61,6 | 88 | 101 | 114 | 690 | |

| 7/4,25 | 12.8 | 34.75 | 47.65 | 69,5 | 99,3 | 114 | 129 | 780 | |

| 7/4,75 | 14 | 43.4 | 59.45 | 86.8o | 124 | 142.7 | 161.3 | 970 | |

| 19/1,00 | 5 | 5.22 | 7.16 | 10.45 | 14.92 | 17.16 | 19.4 | 120 | |

| 19/1,25 | 6.3 | 8.16 | 11 .19 | 16.32 | 23.32 | 26.81 | 30.31 | 180 | |

| 19/1.40 | 7 | 10.24 | 14.04 | 20,47 | 29.25 | 33.64 | 38.02 | 230 | |

| 19/1,60 | 8 | 13.37 | 18.35 | 26,75 | 38,2 | 43.93 | 49.66 | 300 | |

| 19/2,00 | 10 | 20.9 | 28.65 | 41.78 | 50.74 | 59.69 | 68.64 | 77,6 | 470 |

| 19/2,50 | 12.5 | 32,65 | 44,8 | 65.29 | 79.28 | 93.27 | 107,3 | 121,3 | 730 |

| 19/3,00 | 15 | 47 | 64,5 | 94 | 114.1 | 134,3 | 154,5 | 174,6 | 1050 |

| 19/3.55 | 17.8 | 65,8 | 90.27 | 131,6 | 159,9 | 188 | 216.3 | 244,5 | 1470 |

| 19/4,00 | 20 | 83.55 | 114,6 | 167.1 | 203.0 | 238,7 | 274,6 | 310.4 | 1870 |

| 19/4,75 | 23.8 | 117.85 | 161,6 | 235,7 | 286 | 336,7 | 387.2 | 437.7 | 2630 |

- Next: Power Line DIN 48204 ACSR 185/30 95/15 Conductor

- Previous: Bare ACSR 26/7 Type 120/20 150/25 mm2 Conductor